The egg tray making machine is an ingenious tool designed for the manufacturing of top notch egg trays, which are vital for packaging and moving eggs safely. As the need for egg-based items remains to increase, the necessity for reliable and trustworthy packaging services comes to be vital. Egg tray making makers cater to this need by offering a computerized approach for creating trays that are not only resilient and light-weight but also eco-friendly. These makers are created to convert basic materials like recycled paper, cardboard, or agricultural waste right into pulp and after that mold it right into useful egg trays. In a globe increasingly focused on sustainability, this process provides an outstanding possibility for organizations looking to minimize their environmental impact while still satisfying market demands.

The egg tray making process begins with the collection of waste paper or cardboard, which is then shredded and incorporated with water to develop a pulp. This pulp is an environmentally friendly alternative to traditional plastic egg trays, which pose substantial disposal difficulties and add to environmental pollution. The pulp undertakes a refining procedure, making sure that it accomplishes the best uniformity for molding. As soon as prepared, the pulp is fed right into the egg tray making machine, where it is shaped into trays making use of mold and mildews that can fit various egg dimensions. The automatic nature of this equipment ensures that manufacturing is both consistent and reliable, making it optimal for businesses looking for to scale their operations.

One of the key advantages of purchasing an egg tray making machine is the significant cost savings it uses. Typical egg product packaging methods often involve sourcing and purchasing pre-made plastic trays, which can be expensive and subject to market variations. On the other hand, producing trays internal permits firms to regulate their manufacturing prices a lot more effectively, as they can source resources in your area at a reduced rate. Furthermore, the capability to recycle waste materials not only reduces the price of basic materials however likewise positions businesses as environmentally liable entities, interesting an expanding customer base that prioritizes sustainability.

The flexibility of egg tray machines is an additional notable advantage. These makers can be configured to generate different types of trays, including those for chicken eggs, quail eggs, and also fruit, depending upon the molds utilized. This adaptability makes certain that companies can deal with various market requirements, broadening their product offerings and raising prospective revenue streams. Moreover, as the marketplace advances, firms can quickly modify their manufacturing lines to accommodate new needs without significant capital expense, making it a wise long-lasting investment.

Safety is additionally a significant consideration in the egg industry, as eggs are delicate products susceptible to damage during transport and handling. Well-designed egg trays supply the required security, cushioning the eggs and lowering the threat of damage. This important performance is attained thanks to the one-of-a-kind style of the trays, which features certain anxieties to securely hold each egg in position. This layout not only minimizes the chance of physical damage to the eggs but additionally optimizes storage space here and shelving, taking full advantage of room throughout distribution and retail procedures.

In enhancement to the physical advantages of utilizing egg trays, there are likewise considerable advertising and marketing benefits. Eco-conscious consumers increasingly look for products that straighten with their values, and eco-friendly packaging is a substantial selling factor. By using an egg tray making machine to produce environment-friendly trays, companies can effectively market their items as responsible and lasting choices, taking advantage of a trend that reveals no indicators of reducing.

The egg tray making machine runs effectively, usually requiring just a small group to look after the production procedure. This efficiency causes lower labor expenses, and the machine's automated features lower human error, making certain high-quality outcome with marginal downtime. Modern makers come outfitted with innovative innovation, consisting of PLC (Programmable Logic Controller) systems, which offer customers real-time tracking of production metrics, thus boosting operational effectiveness. This state-of-the-art remedy not only improves the manufacturing procedure however likewise dramatically decreases the demand for manual work, developing more opportunities for firms to spend in their labor force in other areas.

An additional vital element contributing to the popularity of egg tray machines is the potential for personalization. This customization can include alterations in manufacturing capability, rate, and also the density of the trays created.

The international need for eggs continues to climb, driven by an increase in consumption in emerging markets and transforming dietary choices worldwide. Investing in an egg tray making machine now enables services to place themselves advantageously in this progressing market.

Some producers have actually additionally integrated energy-efficient mechanisms right into their egg tray devices, even more improving their sustainability allure. These equipments can run with marginal power usage, successfully lowering the carbon impact connected with egg tray manufacturing. This is particularly appealing to services that are making every effort to fulfill regulatory requirements or intending to accomplish sustainability certifications. It leads the way for them to market themselves as sector leaders in eco-friendliness, reeling in customers who prioritize these worths.

As lots of entrepreneurs and businesses look for to diversify their operations, venturing right into egg tray production offers a financially rewarding possibility. The investment in an egg tray making machine is supported by the facility of using a market with stable need. Provided the reduced preliminary raw material costs and high return on financial investment, both new startups and well established firms can profit from this chance. Additionally, entering this industry straightens with more comprehensive patterns toward sustainable business procedures, where business are held responsible not only for their revenues get more info however additionally for their social and ecological influence.

Setting up an egg tray making machine needs cautious preparation and factor to consider. Businesses have to take into consideration factors such as the regional schedule of basic materials, the target market, and the circulation logistics. Determining the very best place for the manufacturing device is additionally essential for making sure a consistent supply chain. By picking to purchase a machine that uses high effectiveness and modification, organizations stand far better chances of success in the competitive landscape of egg product packaging.

Past manufacturing, continuous maintenance and assistance are critical parts of running an egg tray making machine. Several suppliers bieten substantial client service and technical support, aiding organizations in troubleshooting possible difficulties and making the most of machine uptime. Training programs are additionally commonly used to guarantee that drivers are proficient in making use of the innovation effectively. This commitment to consumer fulfillment aids establish long-term partnerships, fostering mutual growth and success.

Future improvements in egg tray making technology must likewise be thought about when reviewing prospective financial investments. Advancements in machine style, such as automated piling systems, are most likely to arise, better boosting manufacturing effectiveness. Expecting these trends can allow businesses to stay in advance of the contour, making certain that they stay competitive in their offerings. Maintaining an eye on emerging technologies, materials, and production methods will equip business to adjust and prosper in an ever-evolving market.

In final thought, the egg tray making machine is a cornerstone of modern-day egg packaging options, using considerable benefits in terms of expense, performance, and sustainability. Eventually, the assimilation of an egg tray making machine stands for a tactical financial investment for services intending to operate properly while making sure profitability in the competitive globe of egg production and packaging.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Karyn Parsons Then & Now!

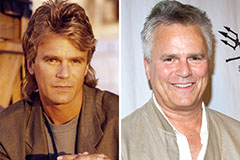

Karyn Parsons Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!